How to Choose an X-Ray Baggage Scanner

At airport cargo screening areas, major logistics hubs, or security checkpoints for large-scale events, selecting the appropriate X-ray security scanner is more than just purchasing a piece of equipment; it is about establishing a reliable standard of perception and decision-making for your security perimeter. Faced with a multitude of models on the market, the key to decision-making lies in deeply understanding the core demands of your specific operational scenario and precisely matching technical specifications to them.

Below, we combine industry insights to outline the core dimensions of selection and naturally illustrate how products with different positioning serve these needs.

1: Decoding Core Dimensions: From Specifications to Practical Performance

Penetration & Aperture Size: Defining Detection Boundaries

Penetration (Steel Equivalent): Directly determines how dense an object the equipment can “see through.” For example, penetration of ≥34mm is sufficient to handle densely packed luggage, parcels, or small cargo, ensuring clear internal structure even when obscured by heavy items.

Aperture Size: This is the first physical checkpoint in selection. It needs to be slightly larger than the largest item in daily circulation while avoiding unnecessary space and energy waste. Common needs can be categorized into tiers:

Standard Aperture (approx. 510x310mm): Suitable for carry-on baggage and mail parcel inspection in offices, courthouses, and small venues.

Large Aperture (approx. 624x429mm): Handles backpacks and medium-sized parcels at airport passenger screening or medium logistics centers, offering better compatibility.

Extra-Large Aperture (1000x1000mm and above): Designed specifically for large cargo, checked luggage, oversized mail parcels, and logistics sorting centers, capable of processing items like whole cartons and large equipment.

Imaging Technology & Material Discrimination: Understanding Item Essence

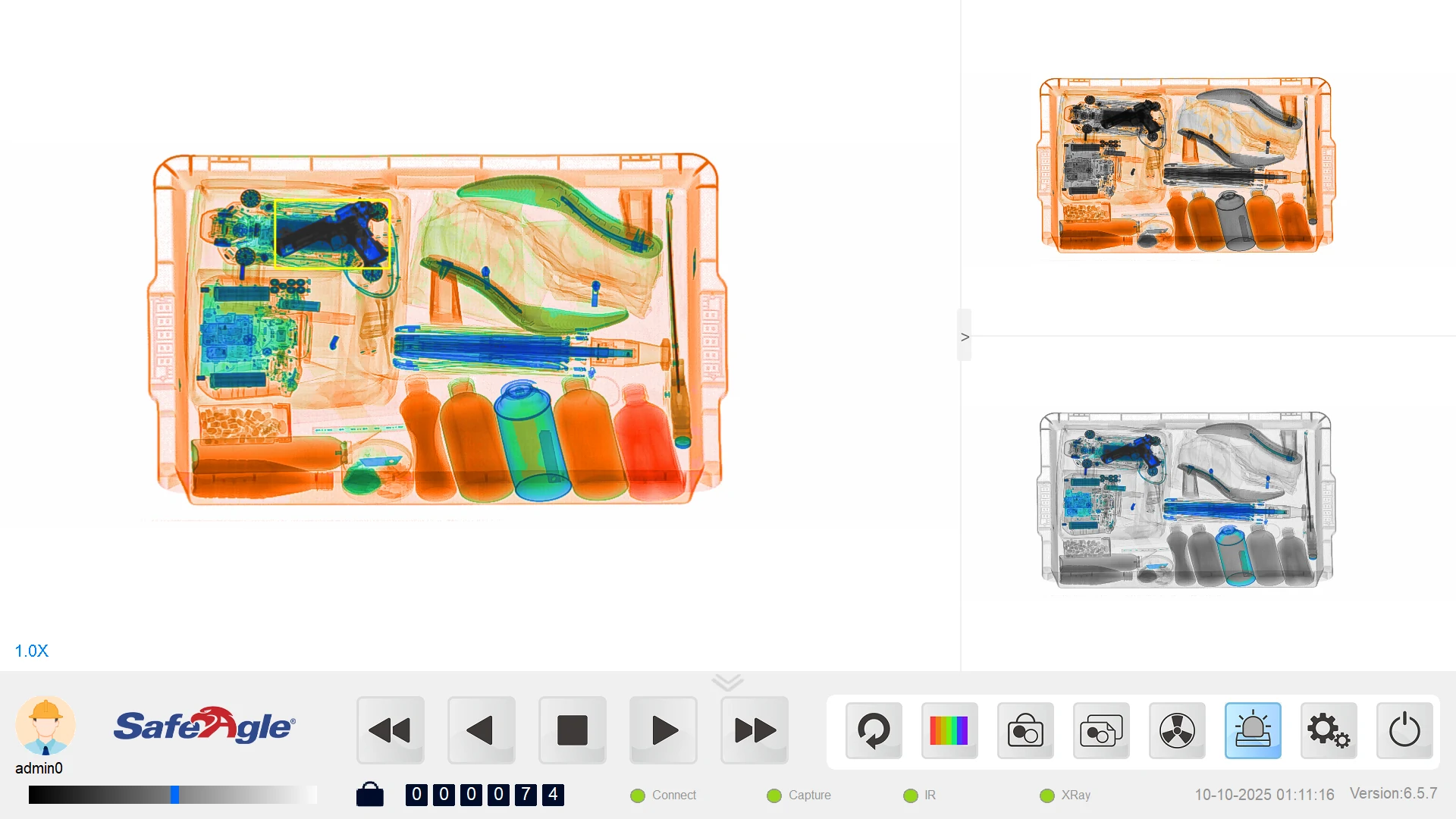

Dual-Energy & Color Imaging: This is the core of modern security scanners. By utilizing a material’s effective atomic number (Zeff), organic materials (e.g., explosives, drugs, plastics) are displayed in orange, inorganic materials (metals) in blue, and mixtures in green. Equipment that supports switching between 4-color (basic) and 7-color (enhanced) imaging modes provides more nuanced material discrimination, particularly beneficial for identifying specific threats against complex backgrounds.

Assistant Detection Algorithms: Advanced devices feature built-in intelligent algorithms that can automatically flag materials within specific Zeff ranges (e.g., corresponding to hazardous liquids, common explosives, or drugs). This provides crucial prompts for operators, significantly improving image interpretation efficiency and accuracy while reducing the risk of missed detections.

Reliability, Efficiency & Adaptability: Ensuring Continuous Operation

Structure & Load Capacity: A robust chassis structure and high-load conveyor belt (e.g., 150kg-250kg) form the physical foundation for handling high-intensity, high-volume operations.

Stability & Maintenance: An X-ray source utilizing sealed oil bath with forced air cooling, coupled with a 100% duty cycle design requiring no warm-up, supports 24/7 continuous operation, greatly enhancing equipment availability and lifecycle.

Environmental Adaptability: A broad operating temperature range (e.g., 0°C to 40°C) and humidity tolerance (up to 95% non-condensing) ensure stable performance in diverse environments, from cold storage warehouses to tropical outdoor settings.

2: Matching Scenarios: How the Safeagle Product Series Addresses Different Challenges

Based on the dimensions above, we can clearly see how different models are tailored for specific scenarios.

For Large Logistics Centers, Airport Cargo Screening, and Major Infrastructure Projects

The core challenges here are handling large cargo or checked luggage of varying sizes with complex contents, coupled with high throughput and extreme reliability requirements.Key Focus Areas: Extra-large aperture size, high penetration capability, high load capacity, and top-tier image clarity.

Corresponding Solution: For instance, the HP-SE100100C Large X-ray Screening System, with its 1-meter square extra-large aperture and 250kg load capacity, can easily accommodate large shipping cartons. Its 36mm steel penetration and 7-color imaging technology allow for precise inspection inside high-density cargo, while its intelligent assistant detection functions provide a double safeguard against potential threats hidden among mixed items. It is an ideal choice for building a high-efficiency, high-reliability cargo security screening perimeter.

For Public Transport, Venues, and Corporate Security

The daily focus is on passenger carry-on luggage, backpacks, and small-to-medium parcels, requiring a balance between security assurance, throughput efficiency, and spatial layout.Key Focus Areas: Appropriate aperture size, clear imaging quality, reliable stability, and moderate footprint.

Corresponding Solution: Standard aperture devices like the HP-SE5030C X-ray Baggage Scanner, with their compact size and sufficient 34mm steel penetration for daily luggage, are perfectly suited. Equipped with intelligent assistant detection and 7-color imaging capabilities, they effectively identify concealed contraband. This makes them ideal for deployment in locations requiring fast and effective inspection of personal belongings, such as subways, museums, and office buildings.

For High-Security Requirements: Airport Passenger Screening, Customs, and Critical Facilities

This represents the most stringent scenario for inspection accuracy, where obstruction from any angle could lead to a missed detection, necessitating multiple viewing angles to eliminate blind spots.Key Focus Areas: Multi-view imaging to eliminate dead angles, excellent image resolution, enhanced penetration capability.

Corresponding Solution: Dual-View X-ray Baggage Scanners (like the HP-SE6040D) scan simultaneously from top and side views, generating two correlated images suitable for 3D analysis. This effectively addresses the challenges posed by overlapping items and significantly improves the ability to identify concealed threats (e.g., knives or liquids attached to case walls). Their 36mm penetration also ensures clear internal details even in densely packed suitcases.

3: Product Key Feature Comparison at a Glance

| Feature Dimension | HP-SE5030C (Standard Aperture) | HP-SE6040D (Dual-View) | HP-SE100100C (Large Aperture) |

|---|---|---|---|

| Core Positioning | Daily Carry-on Baggage & Parcel Security | High-Level, High-Accuracy Security Screening | Large Cargo, Checked Luggage Screening |

| Aperture Size (W x H) | 510 x 310 mm | 624 x 429 mm | 1001 x 1001 mm |

| Max. Load Capacity | 150 kg | 165 kg | 250 kg |

| Typical Steel Penetration | 34 mm | 36 mm | 36 mm |

| Imaging Highlights | 7-Color Imaging, Assistant Detection | Dual-View Imaging, 7-Color Imaging, Assistant Detection | 7-Color Imaging, Assistant Detection |

| Typical Use Cases | Subways, Venues, Mail Inspection, Enterprises | Airport Pax Screening, Customs, Embassies, Data Centers | Logistics Centers, Airport Cargo, Ports, Large Events |

4: Conclusion: Let Technology Serve Your Needs Precisely

Selecting an X-ray baggage scanner is a process of translating specific security requirements into precise technical parameters. Understand that penetration and aperture size define the scope of detection, dual-energy color imaging and intelligent algorithms determine the depth of identification, and reliability engineering ensures the lasting stability of your security perimeter.

Whether processing high volumes of mail, screening airport luggage, or inspecting large cargo, the key is the precise alignment of the equipment’s core capabilities with the scenario’s core challenges. We hope this analysis provides a clear decision-making path for building a more robust and efficient security line for your operations.

- By Safeagle