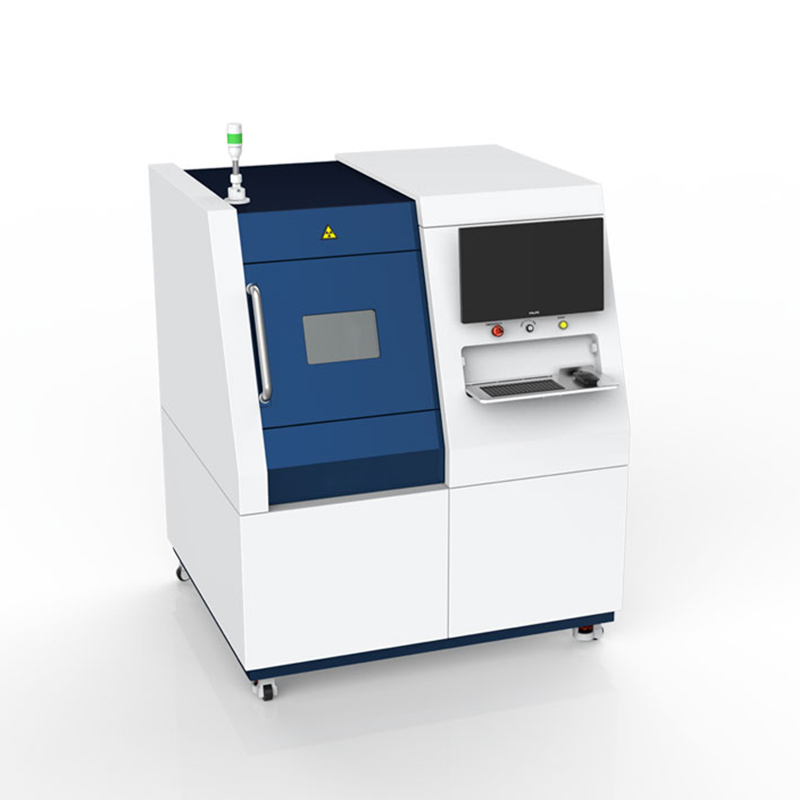

SE-PDR01 Industry PCB X-ray Inspection System

Safeagle SE-PDR01 Industry PCB X-ray Inspection System also known as automated X-ray inspection.

A quality monitoring method for finding hidden defects in circuit boards.

SE-PDR01 Industry PCB X-ray Inspection System Description

The SE-PDR01 Industry PCB X-ray Inspection System product adopts a self-developed carbon nanotube X-ray tube and high-resolution flat panel detector, which can quickly obtain high-quality two-dimensional detection images. The optimal resolution can reach 2.5μm, which can easily meet the size and defect detection requirements of various objects. Widely used in new product development and quality sampling, and failure analysis.

X-ray technology stands out as the optimal method for swiftly and non-destructively examining both the internal and external structures of components with precision. Safeagle CT Solutions specializes in 3D X-ray microscope solutions, providing resolutions down to the sub-micron level for a comprehensive range of applications in both industrial and academic settings.

X-ray Source/strong>

- Working Voltage: 90~150 KV

- Focus Size: 3~15 μm (optional)

- Working Current: 10~ 150 μA

- Light Pipe Type: Closed Tube

GENERAL SPECIFICATIONS

- Type: Digital Flat Panel

- Pixel Size: 49.5 μm (optional)

- Pixel Number: 1300x 1152 (optional)

- Image Area: 64 x 57 mm (optional)

- Gray Scale: 14/16 bits

- System Resolution: 2.5 μm

- Standard Dimensions: 1454 x 1360 x 1785 mm

- Overall Weight: 1000 kg

Related Products

Related products

Get in Touch with us

Fill out more information, We will get back to you within 24 hours.